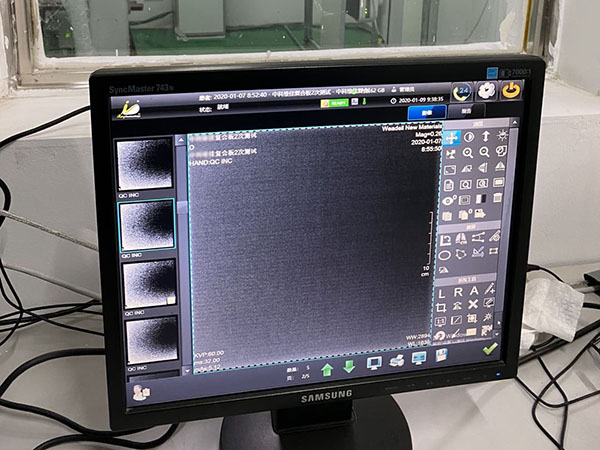

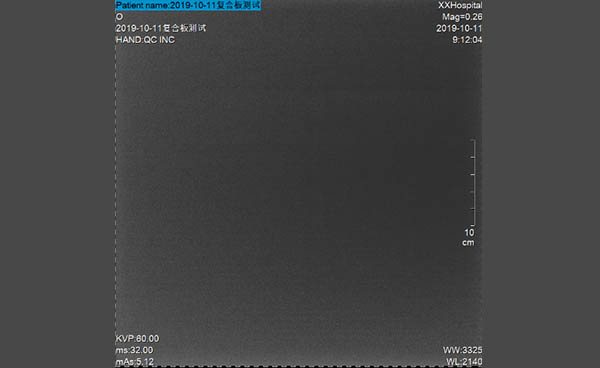

Dedicated Product Inspection System of Radiological Quality

The radiolucency and the quality of imaging results are two particularly important features for products that involve medical x ray use scenarios. In this regard, WEADELL has a complete set of dedicated inspection system and related processes to ensure that all products have perfect quality.

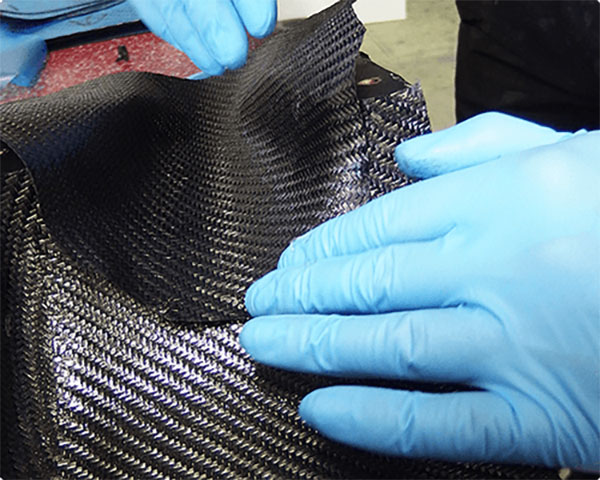

Optional Production of Carbon Fiber

Including autoclave, curing oven, vacuum infusion, manual layering, we master a variety of carbon fiber production processes and advanced equipment, according to your requirements flexible choices can be made.

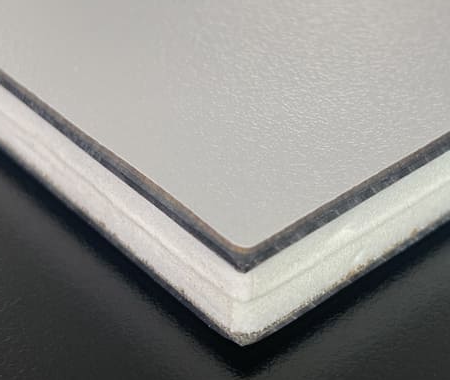

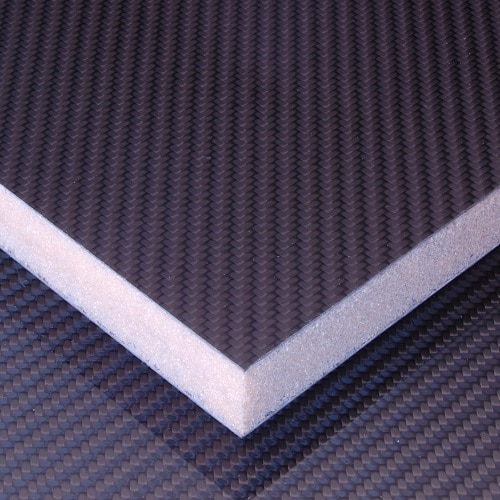

Sandwich Composite Plate Manufacture

Using carbon fiber or melamine phenol resin laminate as the surface, with different core materials, such as rigid foam, honeycomb materials, we can produce a variety of sandwich composite structure plate.

Analysis and Design

Production design from the beginning is the key to a successful product. Design notification production process. Therefore, we attach great importance to the analysis of products and their carbon fiber elements.

We provide consulting services on melamine resin and carbon fiber technology, taking into account budgets, geometry, thickness, threads, seams, etc. We have the expertise and expertise needed to plan projects in a manner that successfully implements them.

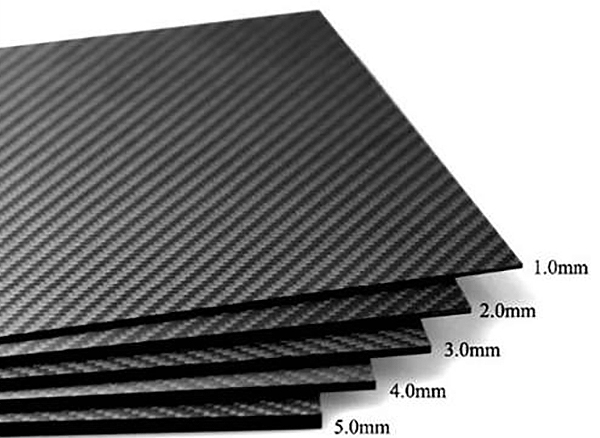

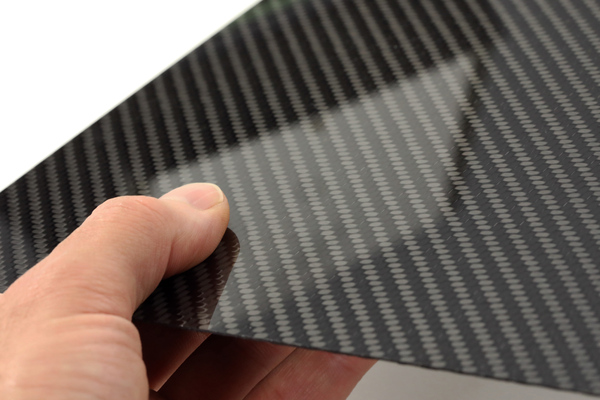

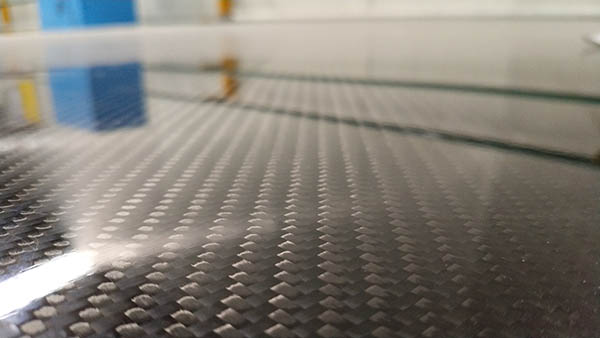

Carbon Fiber Sheets Manufacturing

We supply premium quality carbon fiber sheets with specifications of thickness 0.5-45 mm, of size max. 1000x3600 mm, of material unitary carbon fiber, hybrid (e.g., carbon-aramid or carbon-glass), and with core (honeycomb, rigid foam).

End Product Machining

Product machining follows with a CNC 3-axis milling machine. It ensures precisely repeatability of each product and top-quality edges.

Varnishing Carbon Fiber Surface

Finished carbon fiber composites undergo varnishing to ensure high class top coat. This phase is crucial for premium products manufactured with pre-preg technology. Upon request, we brand the product with the client’s logo before covering with a clear top coat to highlight the branding or origin.

Paint Spray

We offer high quality painting of carbon fiber components.

Assembly

We can also assemble finished products. Our highly skilled specialists guarantee the delivery of the output in a highly professional manner.

Rigorous Quality Control

Rigorous quality control at every phase of production ensures the end product is free of defects and air bubbles or other undesired flaws. Actually, quality control confirms the reliability of the techniques we use, as well as the machines and the competence of our specialists.

Timely Delivery

We know how important timely delivery is to building long term confidence and relationships. Therefore we maintain a stock of our products to ensure prompt delivery or timely order execution.

Autoclave

Maximum operating pressure 8 bar, maximum curing temperature 250° C - for production of premium quality carbon fiber composites (pre-preg).

Autoclave #1: 3 x 6m

Autoclave #2: 0.6 x 8m

Autoclave #3: 3.6 x 8m in coming

Oven

Oven - 4x2x2m, maximum temperature: 220°C.

Hydraulic Press

Heating plates dimensions: 2000 x 3000 mm, pressure 100 tons.

CNC Machining Center (3-Axis)

Operating area: X: 3000 mm, Y: 1530 mm, Z: 300mm.

Sander with a Wide Belt

For sanding sheets to the desired thickness, to an accuracy of 0.05 mm

Refrigeration Storage

About 30 ㎡ where the pre-pregs are stored

Cleanroom

Our cleanroom provides a contamination-free environment to lay up composite materials, ideal for pre-peg lamination

1000 Square Meter

1000 square meters of manufacturing space

A New 5000 square meter is coming soon

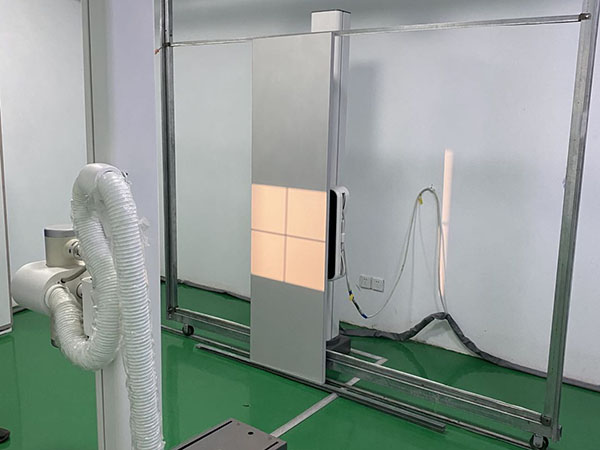

Digital Radiography System

To inspecting the X-ray imaging quality of products